Air compressor: Which one to choose?

There are several situations in which an air compressor is needed.

In this article we explain how different air compressors work and which one to choose for your workshop. Stay there!

Air compressor operation

An is an equipment that transforms the air present in the atmosphere into compressed air under pressure.

Regardless of compressor type, everyone uses the air in the atmosphere in conjunction with an engine to mechanically compress it.

Once compressed, the air proceeds to the storage part of the equipment for a future use.

What’s the air compressor for?

The air compressor can be used for different uses in the day-to-day life of a workshop. We highlight the following:

- Car painting;

- Car wash;

- Fill tires with the proper pressure;

- Sandblast parts.

- Pneumatic keys

In these situations compressed air is an essential complement for the work to be done quickly and, at the same time, successful.

Types of air compressor

-

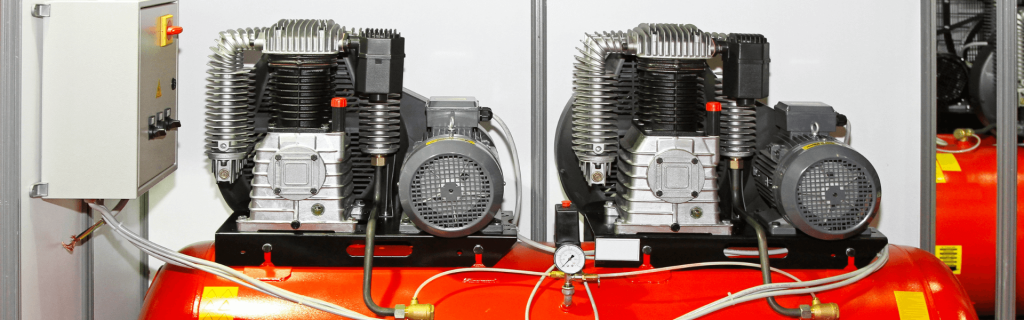

Piston compressor

A piston is used inside the cylinder to compress the air. Because it has a piston inside it is normal for this type of compressor to have oil so that there is less friction between the piston and the cylinder.

Advantages :

- Low price;

- Easy maintenance;

- Suitable for high pressures.

Disadvantages:

- Noisy;

- High compressed air outlet temperatures.

- High oil content in the air pipe.

-

Rotary screw compressor

The rotary screw compressor is one of the most popular and can or cannot be oil lubricated, depending on the needs and user preferences.

About operation, the rotary screw compressor uses two rotors to compress the aire. These rotors rotate in opposite directions generating a little slack between them where the air flows.. This compressed air is pushed into the compressor pressure zone , where it is stored.

Advantages:

- Silent operation mode.

- Large compressed air storage capacity;

- Energy efficient.

- Possibility to recover the energy used.

- Low compressed air temperature.

Disadvantages:

- Highest price.

- More complex construction;

- Increased maintenance;

- Non frequent use will lead condensed water formation within the air storage.

-

Rotary air compressor

The rotary air compressor is the latest of all. This compressor works with two spiral elements.

One of these spirals works inside the other and both inside the compressor engine. Due to the way the spiral moves are created small air formations that move slowly to the storage zone in compressor

Advantages:

- Silent.

- Compact;

- Few parts, which translates into reduced maintenance costs.

- No oil needed.

Disadvantages:

- Low pressure capacity.

- Expensive;

- High temperature compressed output air.

Which air compressor should you choose for your workshop?

Choosing an compressor for a workshop always depends on the frequency of use and the job you have for it.

- If you need a higher amount of air instead of a high pressure, a rotary screw compressor is advisable.

- If it requires high pressures, but with a smaller amount of air it is advisable to buy a piston compressor.

- If it requires a median pressure and capacity, you should choose the rotary air compressor.

Air pressure vs Air storage capacity

As far as the air compressor is concerned, the choose is between pressure and storage capacity.

If you use the air compressor daily to fill a tractor wheel is appropriate to opt for a compressed air with large storage capacity, since it does not need much pressure, but a greater amount of compressed air.

If you use a sandblaster day, where high pressure is an important factor, you should purchase an air compressor that reaches high air pressures.

Prices

A compressor has different values, depending on whether you want to use it for an amateur or a professional use. The values can fluctuate between 50 euros and 5 thousand euros.

![]()