Problems with High Strength Fastener

At present, the development prospects of high strength fastener are good, but there are still some problems in domestic high-strength fasteners,following we will discuss about them.

1. Guarantee the load and the wedge load is unqualified. Guaranteed load and wedge load are the key items in the assessment of the mechanical properties of the product under tensile load. Especially important for high strength fasteners. The guaranteed load is the ability of the product to resist plastic deformation under the specified tensile load. If the target does not meet the requirements, plastic deformation may occur due to the preload and working load, thereby reducing the preload and loosening the connection. The wedge load test is to evaluate the tensile strength and head joint strength of the bolt product. The index is unqualified. Under the action of a large working load, especially the impact load or when the support surface is subjected to the eccentric load, the fracture or Turning around, causing connection failures and even security incidents.

2. The hardness is unqualified. Hardness is also an important indicator to evaluate the mechanical properties of fasteners. The materials used for each performance grade are different. The mechanical performance grade is an important basis when selecting fasteners. The installation load should be determined according to the performance grade. And the installation torque, for a specific material, the hardness should be controlled at a reasonable level, high hardness may reduce the fatigue resistance of the product, some enterprises in order to improve the strength of the product, the hardness is controlled at a higher level, causing some products to exceed the standard.

3. The decarburization layer exceeds the standard. The decarburization layer is also a type A project. Due to decarburization, the surface hardness and strength of the parts are greatly reduced, which seriously affects the surface contact strength and fatigue life of the fasteners, especially the damage to the threaded parts. The main causes of decarburization are decarburization of raw materials, decarburization during material reforming, and decarburization during product heat treatment.

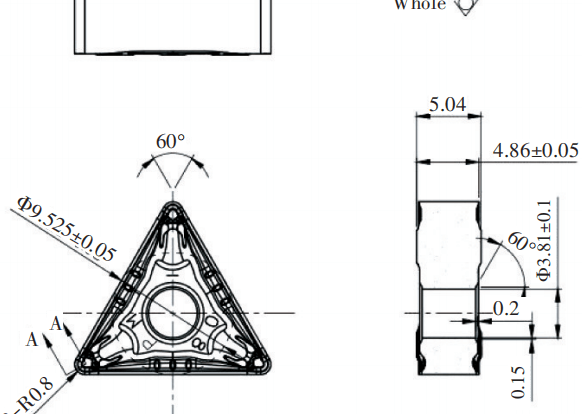

4, The size is out of tolerance. High Strength Fastener is common part, and the interchangeability requirements are high. The size difference will directly affect the interchangeability and even affect the joint strength, anti-loose performance or life. The main reason for the unqualified size is that the process is not properly controlled. In order to save some parts to the lower limit, the equipment is not adjusted in time, and the tool is used in the production process. Secondly, the inspection is ineffective, the process inspection and the factory inspection. Not strict, so that some unqualified batches pass; third is that the measuring tools can not be regularly measured, even using gauges that exceed the wear limit.

ASTM A325 Hex bolt

Stainless Steel Hex Bolts,Structural Bolt,High Quality Hexagon Bolts,High Stretch Structure Bolt Details of ASTM A325 Hex bolt Standard:DIN, ISO,DIN,ANSI,JIS,BS color:black materil:carbon steel alloy steel Grade:ASTM A325 Size:M12-M36 Mark:According to customer’s requirement Quality:Top high quality ASTM A325 Hex bolt Package:Cartons&pallets or according to customer’s requirement 1.Standard:ISO,DIN,ANSI,JIS,BS. 2.Grade:ASTM A325 3.Mark:According to customer’s requirement 4.Size:M12-M36 5.Finish:Plain, black, zinc plated, […]