tarby pump curves

In the field of fluid dynamics, various types of pumps are employed to meet specific needs across a range of industries. One such pump is the Tarby pump, renowned for its efficiency, reliability, and versatility. A crucial aspect of understanding the performance of a Tarby pump lies in analyzing Tarby pump curves. This article will explore what Tarby pumps are, the significance of pump curves, and how to interpret them for optimal application.

What is a Tarby Pump?

Tarby pumps are a type of positive displacement pump that has gained popularity in applications involving the transfer of viscous fluids and slurries. They operate on a simple principle: as the pump’s rotor turns, it creates a vacuum that draws fluid into the pump and subsequently pushes it out under pressure. This characteristic allows Tarby pumps to handle a variety of fluids, including those containing solids, making them particularly useful in sectors like wastewater treatment, mining, and food processing.

The Importance of Pump Curves

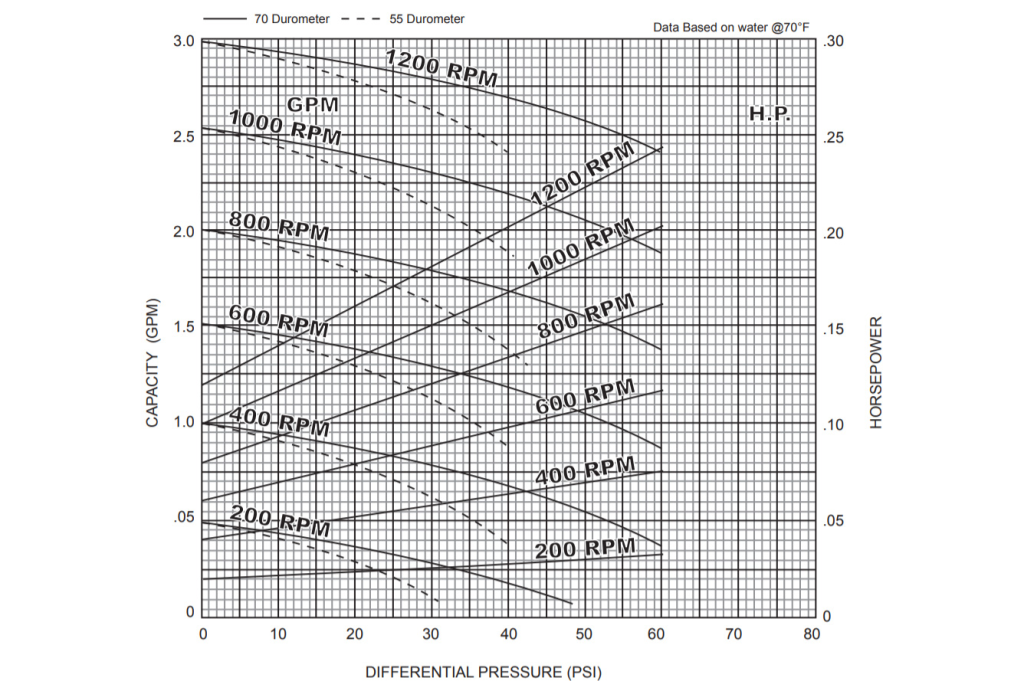

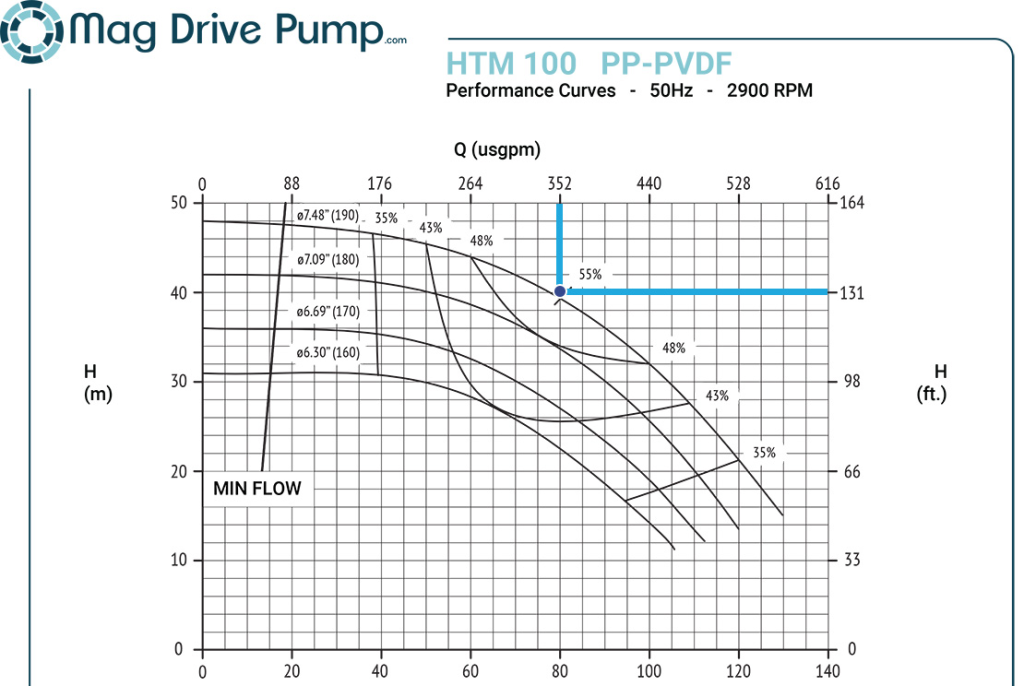

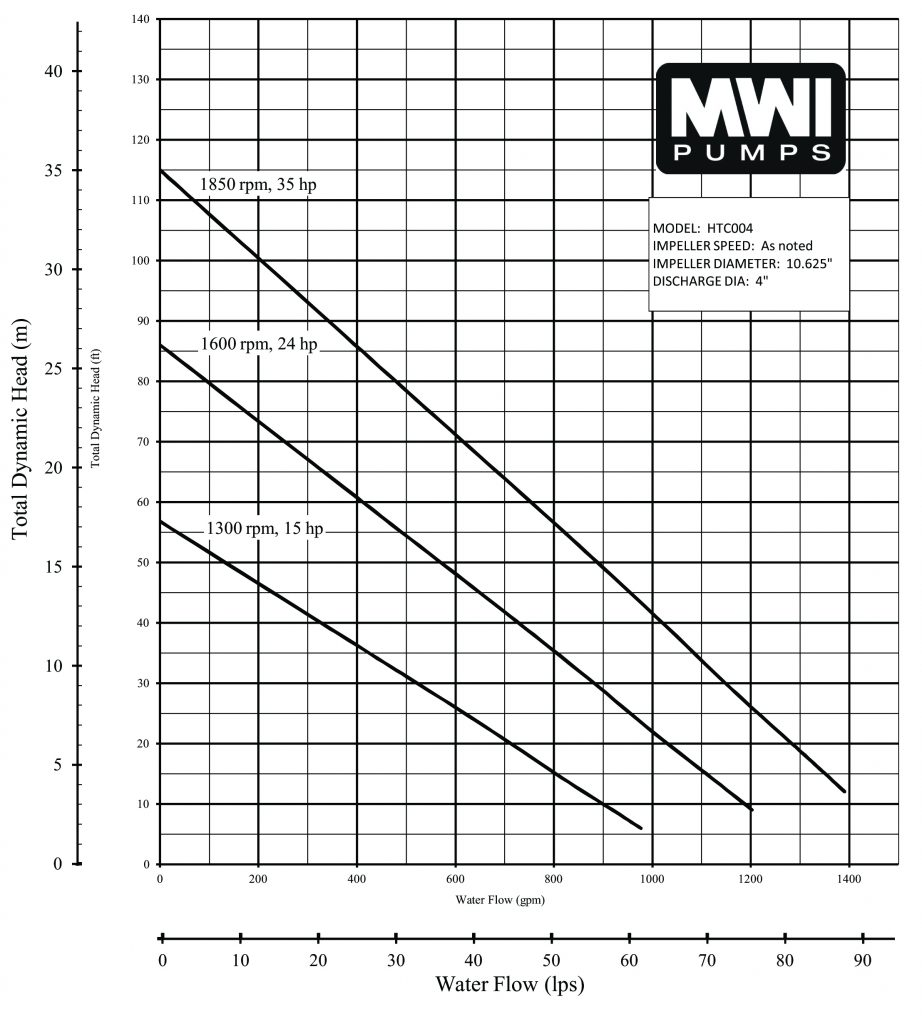

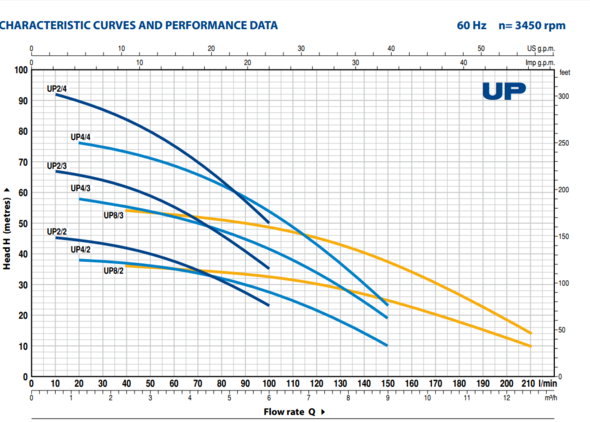

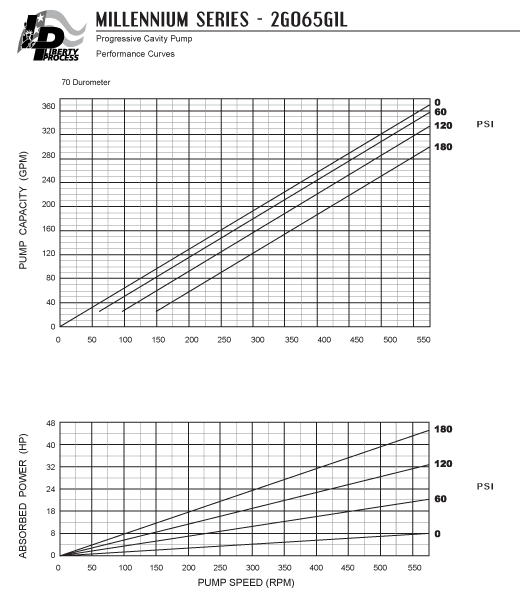

Pump curves are essential tools for understanding how a pump will perform under different conditions. The Tarby pump curves provide graphical representations of the flow rate against the head, efficiency, and other performance metrics of the pump. These curves are integral for selecting the right pump for a specific application, ensuring that it operates efficiently and reliably.

Key Elements of Tarby Pump Curves

- Flow Rate (Q): This represents the volume of fluid the pump can move, typically measured in gallons per minute (GPM) or liters per second (L/s). The curve illustrates how the flow rate varies with changes in pressure.

- Head (H): The head is a measure of the energy imparted to the fluid, often depicted in feet or meters. The head curve demonstrates the maximum height to which the pump can raise the fluid, which is critical for application suitability.

- Efficiency: This component indicates the performance of the pump in converting input power to hydraulic power. Higher efficiency translates into lower operational costs and less wear on pump components.

- NPSH (Net Positive Suction Head): NPSH is crucial for preventing cavitation, a phenomenon that can damage the pump. The curve helps operators to determine the minimum NPSH required for safe operation in various conditions.

Analyzing Tarby Pump Curves

Interpreting Tarby pump curves allows operators to identify the best operating points for the pump. Each curve typically includes a specific point known as the Best Efficiency Point (BEP), where the pump operates most efficiently. Operating near this point ensures minimal energy consumption while maximizing flow rate and head.

If a pump operates significantly outside this optimal range, it may experience various issues. For instance, excessive flow rates can lead to increased wear and energy costs, while operating at low flow rates may cause unsteady operation and reduced efficiency.

Selecting the Appropriate Pump

Choosing the right Tarby pump requires careful consideration of the specific requirements of the application. Factors such as fluid type, viscosity, temperature, and solid content are vital in making an informed decision.

For example, in industries dealing with heavy slurries, the ability of a Tarby pump to handle solids without clogging is critical. The pump curves provide valuable data for comparing different models, ensuring that the selected pump can meet the application’s demands effectively.

Maintenance and Monitoring

Regular monitoring of pump performance against the Tarby pump curves can aid in predictive maintenance. If performance deviates significantly from what the curve suggests, it may signal potential problems such as wear or obstructions. Timely intervention can prevent costly breakdowns and extend the lifespan of the pump.

Conclusion

Understanding Tarby pump curves is essential for optimizing the performance of Tarby pumps in various applications. These curves offer insights into flow rate, head, efficiency, and NPSH, helping engineers and operators make informed decisions about pump selection and operation.

By leveraging the information provided by these curves, industries can enhance their operational efficiency, reduce downtime, and cut costs associated with maintenance and energy consumption. As fluid handling applications continue to evolve, the significance of Tarby pump curves in ensuring optimal performance will remain a critical focus for engineers and operators alike.

In conclusion, whether you are in wastewater treatment, food processing, or any industry relying on fluid dynamics, mastering the use of Tarby pump curves will undoubtedly contribute to improved performance and reliability in your operations.