Seepex Pump Manual: A Comprehensive Overview

When it comes to industrial pumping solutions, Seepex pumps stand out for their reliability and efficiency. This comprehensive overview of the Seepex pump manual provides essential insights into the operation, maintenance, and troubleshooting of these advanced pumps. Whether you are a seasoned technician or a newcomer to the field, understanding the contents of the Seepex pump manual is crucial for optimizing performance and extending the lifespan of your equipment.

Introduction to Seepex Pumps

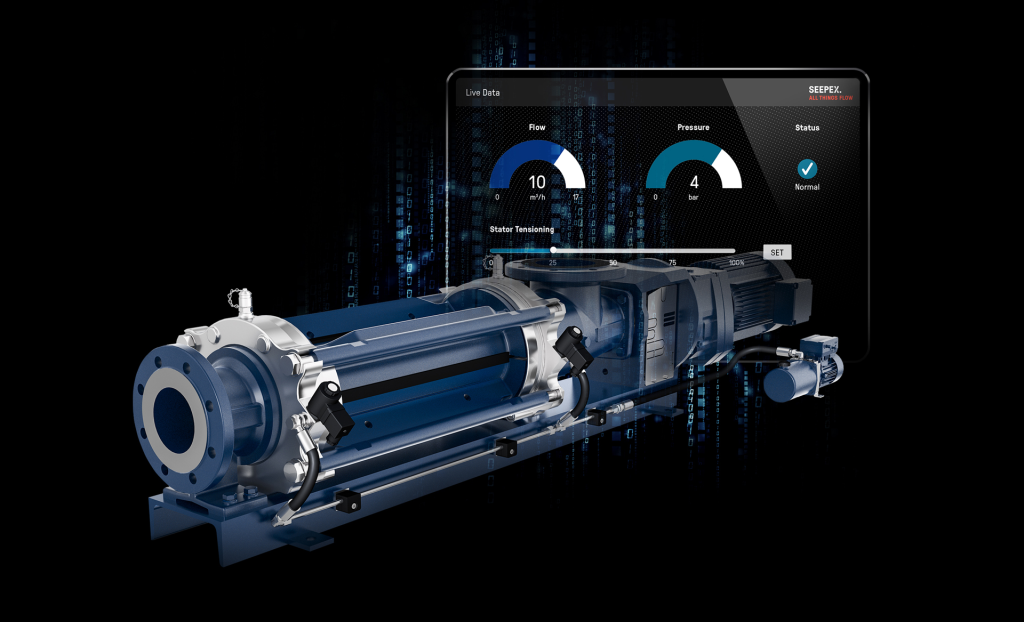

Seepex pumps are positive displacement pumps specifically designed for the transportation of viscous and abrasive materials. They are widely used across various industries, including wastewater treatment, food and beverage, and chemical processing. The unique design of Seepex pumps allows them to handle challenging materials, making them a popular choice in demanding applications.

Key Components of Seepex Pumps

The Seepex pump manual details the main components of the pump, each of which plays a critical role in its operation:

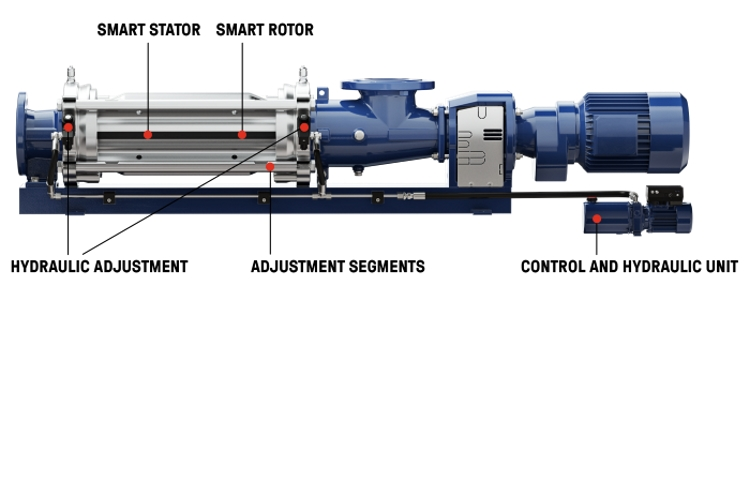

Rotor and Stator

The rotor and stator are the heart of the Seepex pump. The rotor, which is typically made of high-quality materials, rotates within the stator to create a cavity that moves the fluid through the pump. The precise fit between these components is vital for efficient operation.

Drive System

The drive system powers the rotor, and it can vary based on the specific model of the pump. Understanding the type of drive system used is essential for proper maintenance and troubleshooting.

Seals and Bearings

Seals and bearings ensure that the pump operates smoothly and without leaks. Regular inspection and maintenance of these components are necessary to prevent operational issues.

Operating Principles

The Seepex pump manual explains the operating principles that allow these pumps to function effectively. The positive displacement mechanism creates a continuous flow of material, which is particularly useful for handling viscous fluids. This method of operation helps maintain a consistent flow rate, regardless of changes in pressure.

Flow Characteristics

Seepex pumps are designed to provide a steady flow, making them ideal for applications where precise dosing and metering are required. The manual outlines how to adjust the flow rate based on the specific needs of your application.

Installation Guidelines

Proper installation is crucial for the optimal performance of Seepex pumps. The manual provides step-by-step instructions to ensure that the pump is installed correctly. Key considerations include:

- Location: Choose a location that allows for easy access for maintenance and inspection.

- Piping: Ensure that the piping system is compatible with the pump specifications to avoid blockages and leaks.

- Alignment: Proper alignment of the pump and motor is essential to prevent excessive wear on components.

Maintenance Procedures

Regular maintenance is vital for the longevity and efficiency of Seepex pumps. The manual includes detailed maintenance procedures, which typically involve:

Routine Inspections

Regular inspections help identify potential issues before they become major problems. The manual emphasizes checking seals, bearings, and other critical components.

Lubrication

Proper lubrication is necessary to ensure that the moving parts operate smoothly. The manual provides guidelines on the types of lubricants to use and the frequency of lubrication.

Cleaning

Cleaning the pump and its components is essential, especially when handling abrasive materials. The manual suggests specific cleaning agents that are safe for use with Seepex pumps.

Troubleshooting Common Issues

Despite their reliability, Seepex pumps may encounter issues from time to time. The manual offers a troubleshooting section that addresses common problems, such as:

Low Flow Rate

A decrease in flow rate can indicate blockages in the piping or wear in the rotor and stator. The manual advises on steps to diagnose and rectify this issue.

Vibration and Noise

Excessive vibration and noise may signal misalignment or worn bearings. The manual includes procedures for checking alignment and replacing bearings if necessary.

Leaks

Leaks can occur due to worn seals or improper installation. The manual provides guidelines for identifying the source of leaks and recommendations for repairs.

Conclusion

The Seepex pump manual serves as an invaluable resource for anyone involved in the operation and maintenance of Seepex pumps. By understanding the key components, operating principles, installation guidelines, maintenance procedures, and troubleshooting techniques outlined in the manual, users can ensure the optimal performance of their pumping systems. Proper adherence to the guidelines in the Seepex pump manual not only enhances efficiency but also extends the lifespan of the equipment, ultimately leading to reduced operational costs and improved productivity.

Whether you are new to Seepex pumps or looking to deepen your knowledge, familiarizing yourself with the manual is the first step toward mastering these robust pumping solutions.