How To Choose Carbide Circular Saw Blades Correctly? – UKO Blog

Carbide saw blades are the most commonly used cutting tools for wood product processing, and their quality is closely related to the quality of processed products. The correct and reasonable selection of carbide circular saw blades for wood is of great significance for improving product quality, shortening the processing time, and reducing processing costs.

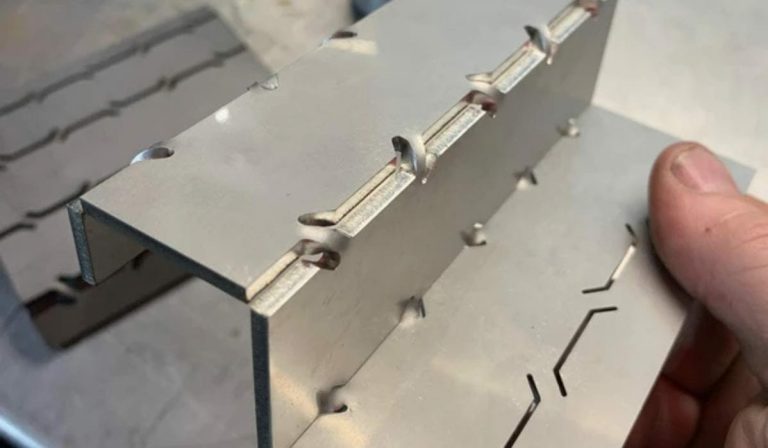

Tungsten carbide circular saw blades include the parameters, such as the saw tips grade, the material of the body, the tooth shape, the angle, the diameter, the number of teeth, the thickness, the bore size and other parameters. These parameters determine the processing capacity and cutting performance of the saw blade. Today I will share some tips when we choose a tungsten carbide saw blade, the following parameters of the saw blade should be selected correctly according to the needs.

- Choose carbide tips grade

Because tungsten-cobalt-based cemented carbide has better impact resistance, it is more widely used in the wood processing industry. The commonly used model in wood processing is YG8-YG15.

2. Choose the material of the body

65Mn spring steel has good elasticity and plasticity, and the material has good hardenability through economic heat treatment. Its low heating temperature and easy deformation can be used for saw blades that require low cutting requirements.

Carbon steel has high thermal conductivity, but its hardness and wear resistance drop sharply when it is exposed to 200°C-250°C, the heat treatment deformation is large, the hardenability is poor, and the tempering time is long and easy to crack. It could make economical saw blade, such as T8A, T10A, T12A, etc.

Compared with carbon steel, alloy tool steel has better heat resistance, wear resistance and better handling performance. The heat deformation temperature is 300°C-400°C, which is suitable for manufacturing high-end carbide circular saw blades.

High-speed tool steel has good hardenability, strong hardness and rigidity, and less heat-resistant deformation. It belongs to ultra-high strength steel with stable thermoplasticity and is suitable for manufacturing high-end ultra-thin saw blades.

3. Selection of saw blade tooth type

The tooth type of the circular saw blade is divided into left and right teeth, tapered teeth, flat teeth, trapezoidal teeth, crescent teeth, etc. In actual use, the choice is mainly based on the type of raw material being sawed.

- The left and right teeth are suitable for opening and horizontal sawing of various soft and hard materials and particle boards. The left and right teeth equipped with anti-repulsion protection teeth are suitable for longitudinal cutting of various boards with tree nodes. The left and right teeth saw with negative rake angle Because of the sharp saw teeth and good cutting quality, the blade is usually used for sawing of veneer.

- Tapered teeth are often used in the slot saw blades of panel saws. When sawing double-faced wood-based panels, the slot saw completes the grooving of the bottom surface, and the main saw completes the sawing of the board to prevent the saw edge from falling apart Ballast phenomenon.

- Flat teeth are mainly used for sawing of ordinary wood. This kind of saw blade has a lower cost but a rougher saw.

- The combination of trapezoidal teeth and flat teeth can also obtain high cutting quality without slotted saw blades, and there will be no veneer cracking during sawing. It is suitable for sawing various double veneer wood-based panels.

4. Choice of saw teeth angle

The angle parameter of the saw teeth part is more complicated, and the correct selection of the angle parameter of the saw blade is the key to determining the quality of sawing. The most important angle parameters are rake angle, rear angle and wedge angle.

The rake angle mainly affects the force consumed by sawing wood chips. The rake angle is generally between 10-15°. The larger the rake angle, the better the sharpness of the saw tooth cutting, the lighter the sawing, the more effortless saving. Generally, when the material to be processed is soft, choose a larger rake angle, otherwise, choose a smaller rake angle. The clearance angle of cemented carbide saw blades is generally 15°.

5. The number of the saw teeth

Generally speaking, the more teeth, the more cutting edges can be cut per unit time, the better the cutting performance. However, the more cutting teeth, the more cemented carbide is needed, and the higher the price of the saw blade. However, the teeth are too dense and the gap between the teeth The smaller chip capacity will easily cause the saw blade to heat up; in addition, there are too many saw teeth. When the feed amount is not properly matched, the cutting amount of each tooth is small, which will increase the friction between the cutting edge and the workpiece and affect the service life of the cutting edge. Usually the tooth spacing is 15-25mm, and a reasonable number of teeth should be selected according to the material to be sawed.

6. The thickness of the saw blade

In theory, we hope that the thinner the saw blade is, the better, but the sawing is actually a consumption. The material of the saw blade and the process of manufacturing the saw blade determine the thickness of the saw blade. When choosing the thickness of the saw blade, the stability of the saw blade and the material to be cut should be considered.

7. The circular saw blade sizes

The diameter of the saw blade is related to the sawing equipment used and the thickness of the sawing workpiece.

For small circular saw, and the cutting speed is relatively low; large circular saw has higher requirements for the saw blade and sawing equipment, and the sawing efficiency is also high.

8. Choice of bore size

The bore size is a relatively simple parameter, which is mainly selected according to the requirements of the equipment, but in order to maintain the stability of the saw blade, it is best to choose a larger bore size for the saw blade above 250mm. At present, the diameter of standard parts designed in the market is mostly 20mm hole for 120mm and below, 25.4mm holes for 120-230mm outer diameter, 30mm bore size for more than 250mm outer diameter, and some equipment also have 15.875mm bore size. The mechanical aperture of multi-blade saws is relatively complicated. There are many keyways to ensure stability. Regardless of the size of the hole, it can be modified by a CNC lathe machine or a wire cutting machine.

The choice of cemented carbide saw blades is related to so many parameters. It seems very complicated. In fact, as long as you find a suitable professional supplier, it is easy.