How to maintain and repair the woodworking edge banding machine? – UKO Blog

If you want to have a long life of the equipment, you need to maintain it well, so how should the edge banding machine be maintained?

1. Keep all parts of the body clean. For example, the glue brought by the board near the glue pot will dry to other parts, which will directly affect its normal work.

2. There will be a large number of edge banding chips cut down in the pre milling part, the end trimming part and the trimming and scraping part. Even if there is a dust suction device, it will not be very clean. The flying edge banding chips will affect the sliding and rolling parts, and also affect the trimming. So every time we have to clean up the edge band scraps.

3. Inspection of operating parts, regularly check the sound and temperature of each operating part for abnormal noise and heating.

4. Refuel the running parts regularly.

There are also maintenance methods, so if it breaks down, how to repair it?

Problem 1: there is a problem in the pressing part of the edge banding machine, which leads to the abnormal operation of the trimming and polishing equipment.

Cause: the plate is not pressed tightly, or there is height before and after the vertical plate. When the plate moves to the gluing part, the gluing wheel and pressing wheel exert certain pressure on the side of the plate, resulting in the displacement of the plate and deviation from the baseline, resulting in the subsequent process can not be completed.

Solution: smoothly done or easily solved the problem by tightening the plank and the tightness of the front and back.

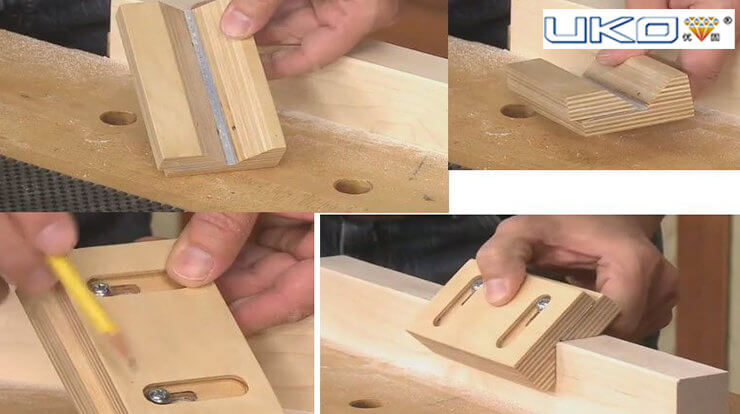

Problem 2: the trimming datum is not found.

Reason: the trimming knife can precisely trim the edge strip to the ideal line, thanks to the horizontal guiding rule (diagonal wheel or arc supporting plate) and vertical guiding rule (profiling wheel) beside the trimming knife. If they can not cling to the moving plate, it is bound to be unable to repair the right line.

Solution: put a long plate with flat end face into the edge banding machine (pay attention not to glue). When the plate moves to the position where it can cover polishing, scraping, finishing and roughing, stop the conveyor belt, take the plate surface as the benchmark, put the horizontal and vertical reference pieces mentioned above on the plate, put the cutting edge of the cutter close to the edge of the plate, and wait for the back to fine tune and straighten Until the ideal effect appears.

Problem 3: loose screws cause unstable trimming.

Solution: find the benchmark, tighten the screw, adjust the tool.

I hope the above shares will be helpful in your work!