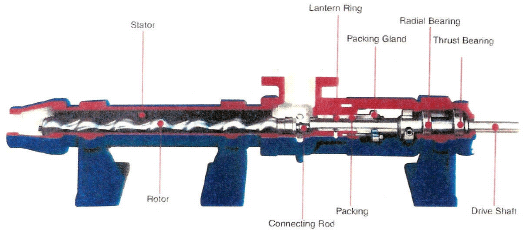

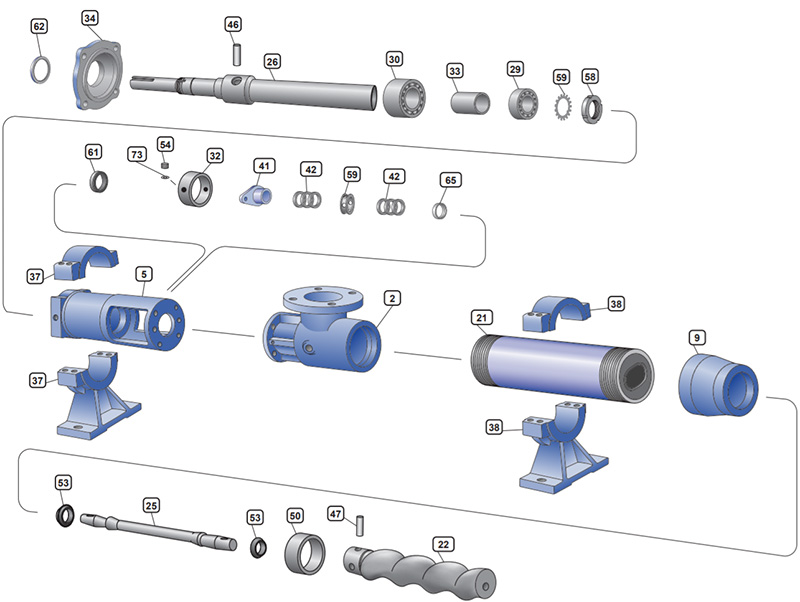

moyno pump parts diagram

Understanding Moyno Pump Parts: A Comprehensive Guide

The Moyno pump is a well-known name in the world of positive displacement pumps, widely used in various industrial applications for transferring fluids. Understanding the components of these pumps is essential for effective operation and maintenance. In this article, we’ll delve into the intricacies of the Moyno pump parts diagram, breaking down each component and its function.

Overview of the Moyno Pump

Moyno pumps are recognized for their efficiency and reliability in handling challenging pumping tasks. These pumps utilize a robust design that features a helical rotor and an elastomeric stator, allowing them to move fluids with a high viscosity and solid content. The modular design of the pump makes it adaptable, and understanding the parts is vital for troubleshooting and repairs.

Key Components of the Moyno Pump

- Helical Rotor:

The heart of the Moyno pump, the helical rotor is responsible for creating the suction needed to draw in the fluid. Its unique shape allows for smooth and continuous flow, making it ideal for a wide array of fluids, from sludges to chemicals. - Elastomeric Stator:

Paired with the rotor, the elastomeric stator encases the rotor and creates a cavity through which the fluid is moved. The material of the stator can vary depending on the application, offering different levels of resistance to chemicals and temperature. - Suction and Discharge Ports:

These are critical for connecting the pump to the pipeline system. The suction port draws the fluid into the pump, while the discharge port releases it under pressure. Proper alignment and sealing of these ports are essential to prevent leaks and maintain efficiency. - Frame and Base:

The frame supports the entire pump assembly, providing stability during operation. The base is typically engineered to absorb vibrations, ensuring smooth functioning and longevity of the pump. - Motor:

Depending on the application, Moyno pumps can be powered by various types of motors—electric, hydraulic, or even gas-powered engines. The choice of motor greatly influences the pump’s performance and energy efficiency. - Gearbox:

In some configurations, a gearbox may be included to adjust the speed and torque of the rotor. This addition allows for fine-tuning of the pump’s operational characteristics, especially when dealing with varying fluid viscosities. - Seals and Bearings:

Seals are crucial for preventing leaks from the pump casing, particularly when handling hazardous materials. Bearings assist in the smooth rotation of the rotor, reducing friction and wear over time.

Understanding the Moyno Pump Parts Diagram

A Moyno pump parts diagram serves as a visual representation of these components, illustrating how each part interacts within the pump system. This diagram is an invaluable resource for maintenance personnel, engineers, and operators alike, aiding in troubleshooting issues and performing routine inspections.

When examining the diagram, it’s essential to familiarize yourself with the various labels and annotations that describe each part. Look for the specifications regarding materials, measurements, and compatible components. This information is crucial, especially when ordering replacement parts or retrofitting an existing pump system.

Maintenance Tips

Regular maintenance of Moyno pumps is key to ensuring long-lasting performance. Here are a few tips based on the components highlighted:

- Inspect Rotors and Stators: Check these parts regularly for wear and tear. Over time, the elastomeric stator can degrade, impacting the pump’s efficiency.

- Monitor Seals: Regularly examine the seals for any signs of leakage. Early detection can prevent larger issues that may require extensive repairs.

- Lubricate Bearings: Proper lubrication of the bearings is essential to reduce friction and extend their lifespan.

- Check Alignment: Ensure that the motor and gearbox are correctly aligned. Misalignment can cause excessive wear on components and lead to failure.

Conclusion

Understanding the Moyno pump and its parts is critical for anyone involved in its operation or maintenance. The Moyno pump parts diagram is a key tool that helps visualize and understand the assembly of the pump. By keeping the pump well-maintained and understanding the function of each component, you can ensure smooth operation and extend the life of this vital industrial equipment. Whether you are dealing with wastewater, food processing, or chemical transfer, the Moyno pump continues to be a reliable choice, thanks to its innovative design and engineering excellence.