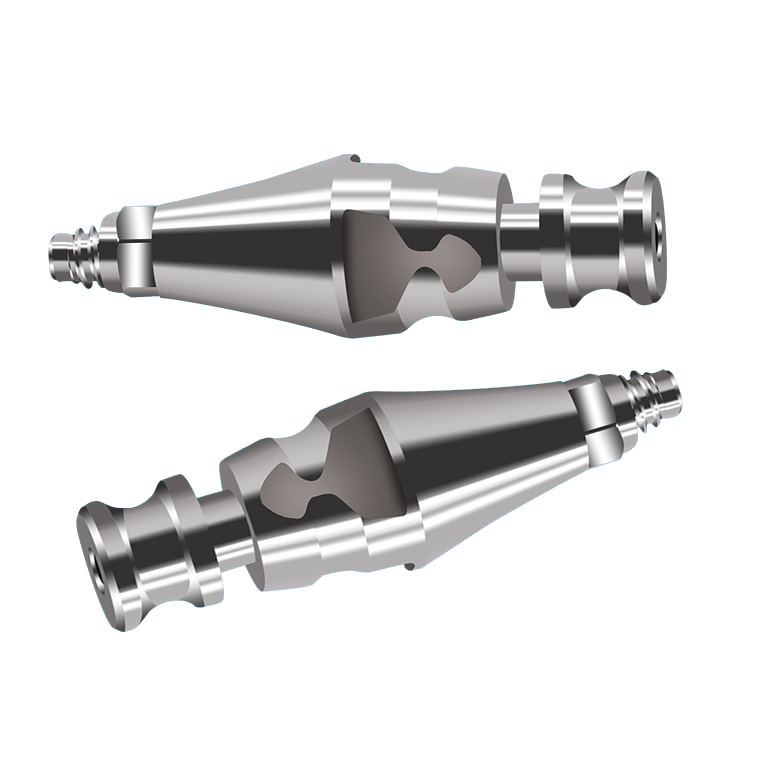

Pump Coupling With Plum Blossom Gasket

The plum coupling is composed of two semi-couplings with convex claws and a plum-shaped flexible non-metallic element whose hardness can be adjusted. By embedding the plum-shaped flexible element into the two semi-couplings to realize the connection, it has the characteristics of compensating the relative displacement of the two axes, reducing vibration and buffering, simple structure and easy maintenance without lubrication.

Flexible plum blossom coupling is made up of semi-shaft coupling with the same protruding claw and flexible component.utilizing the plum blossom elastic component put between the protruding claw and two half shaft coupling.in order to realize the connection of two semiaxis devices.

Jaw coupling has compensating by two axle to be relative skew,reducing shaking buffering.smaller diameter simple structure.without lubricating.bearing large capacity,and convenient repair But the semi-shaft coupling needs to move along the axial while changing the elastic component.

Claw coupling is suitable for two with axis,start frequent,positive and negative change,low-speed and medium speed.medium and small powerrotate axle department,requiring working dependability high working position;it is not suitable for the heavily loaded and restricted axial in size.Two axis put in the difficult position after exchange of flexible component.

LMPK Plum-shaped Flexible CouplingLMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.

LMZ-II Plum-shaped Flexible CouplingLMZ-II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.

LMZ-I Plum-shaped Flexible CouplingLMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.

LMS Plum-shaped Flexible CouplingLMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.

LMD Plum-shaped Flexible CouplingLMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.

LM Plum-shaped Flexible CouplingLM Plum-shaped Flexible Coupling is the basic form of this series of couplings.

« Pump Coupling With Plum Blossom Gasket » Post Date: 2023/9/16

URL: https://www.rokeecoupling.com/en/blog/pump-coupling-with-plum-blossom-gasket.html

Tags:

Flexible Pump Coupling,

Prev: Manufacturer Of Semi Open Plum Blossom Coupling

Next: Flattening Machine Universal Coupling

- Flexible Pump Coupling Drawing

- Diaphragm Pump Couplings

- Manufacturer Of High Elastic Toothed Water Pump Coupling

- Flexible Pump Coupling

- Flexible Pump Coupling Design

- Types of Flexible Pump Couplings

- Flexible Pump Coupling Calculation

- Flexible Pump Coupling Working Principle

- Flexible Pump Coupling Torque

- Flexible Pump Coupling Brands

Do excavators need pump couplings?

Excavators do not typically require pump couplings in their hydraulic systems. The term “pump couplings” refers to devices used to connect the hydraulic pump to the engine or power source. In excavators, the hydraulic pump is usually directly driven by the engine through a mechanical connection, such as a belt or gear mechanism. This eliminates the need for additional pump couplings.

However, it’s worth noting that excavators may have various types of couplings in their hydraulic systems, such as hydraulic quick couplers for attaching and detaching various types of excavator attachments, especially hydraulic attachments, such as hydraulic hammer, hydraulic scrap magnet, or couplings for connecting hydraulic lines and hoses. These couplings facilitate the transmission of hydraulic fluid and power within the excavator’s hydraulic system, enabling the operation of various functions and attachments.