Solution to Problems In The Process of Disassembly And Disassembly of Bolt Tensioner

Solution to Problems In The Process of Disassembly And Disassembly of Bolt Tensioner

As an important special tool for the maintenance of main and auxiliary engines of ships, hydraulic tensioners are irreplaceable. In reality, there are still quite a few people who are unclear about its principles, leading to time-consuming and labor-intensive inspections and repairs, and sometimes broken tools and equipment.

Here, TorcStark will combine personal practical experience to introduce the detailed working process of the tensioner with pictures and texts.

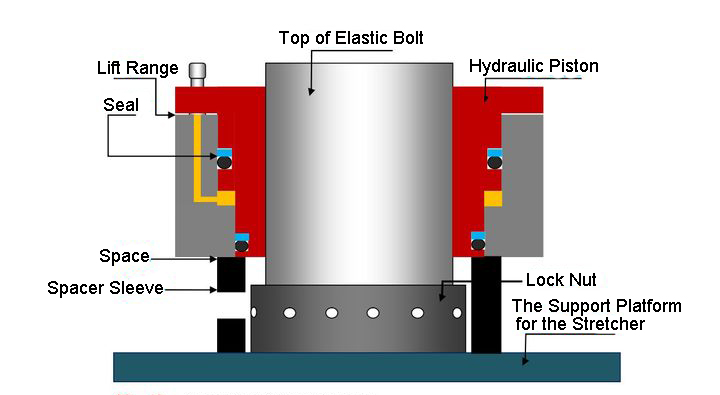

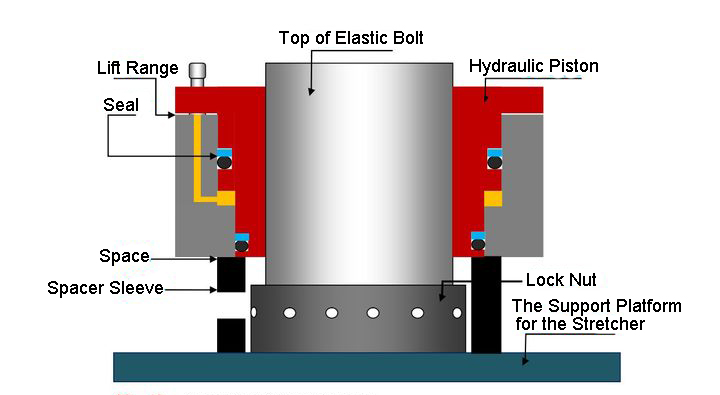

Picture demonstration of the disassembly process of the tensioner:

1. Install the tensioner assembly on the bolt head;

2. Input the pressure oil into the tensioner, and the tensioner shell moves downward under the action of the pressure oil (the absolute position of the hydraulic piston does not change at this time), the gap in the figure becomes 0, and the lift of the hydraulic piston increases (almost exactly as shown in the previous step) Gap value in).

3. Continue to pressurize to almost the pressure specified in the Manual. The nut will be separated from the tensioner platform due to the elongated bolt, resulting in a gap as shown in the figure above. At this time, the nut can be moved with the lever, and the lift will be slightly increased again.

4. When the nut is in the loosening direction, it is enough to feel that the height between the nut and the supporting platform is greater than the lift. If it is not clear, just let it go until it can no longer be loosened, and then just turn around.

5. When the oil pressure is removed, the hydraulic piston will be stretched back by the tensile force of the elastic bolt, and the nut will also fall down (if the height of the loosened nut and the support platform is high enough, the bolt will retract to the initial installation position The nut will not stick to the support platform). After all the oil pressure is removed, be sure to move the nut to see if it can be moved.

Common problem analysis:

1. How are the hydraulic bolts locked?

The hydraulic bolt is stretched by a hydraulic tensioner, then screwed on the nut, and locked by the reverse tension of the elastic bolt after the pressure is relieved.

2. Why is the hydraulic bolt locked again after the pressure is released and after it is clearly loosened. At this time, two situations should be distinguished:

1) The upper edge of the nut is topped by the tensioner, and neither the tensioner nor the nut can move:

Reason:

Excessive loosening will cause the bolt to return to its original state and be held up after the pressure is removed (because even the small section of bolt from the nut to the upper edge will be slightly elongated). This is also the reason why it cannot be completely loosened to the end.

Solution:

Re-pressurize the tension bolt until the nut can be loosened in the tightening direction (about 1/2-3/4 turn), and then remove the oil pressure.

2) The lower edge of the nut is topped by the supporting platform, and the tensioner can move:

Reason:

The nut loosening and unloading stroke is insufficient (basically caused by the insufficient height of the distance sleeve), and the bolt cannot return to the original length position after the oil pressure is removed.

Solution:

All bolts must be disassembled more than 2 times; another way is to make a large gasket when the hydraulic tensioner has enough lift, and increase the height of the distance sleeve to disassemble successfully at one time.

3. After the pressure is relieved, the nut can be moved, but the tensioner cannot be disassembled.

Reason 1:

When the tensioner was initially installed, there was no rotation after tightening, so that after the pressure was removed, the tensioner was pulled by the bolt and topped on the lower platform (equivalent to the tensioner replacing the nut function).

Solution:

Tighten the nut according to the tightening procedure, and then rotate the tensioner a certain number of revolutions according to the disassembly procedure (usually there are instructions in the Manual).

Reason two:

The height of the distance sleeve is enough, the lifter may not have enough stroke: this is rare, unless the matching special lifter is wrong (someone may ask, how can the nut be removed if the stroke is insufficient? This is because when disassembling, After the bolt has been pulled in place, just pull it a little bit more.)

4. Why does the tensioner rotate when removing the bolt?

Theoretically speaking, when rotating the tensioner, the longitudinal lift must be greater than the stretched length of the elastic bolt. Otherwise, the tensioner will be topped by the supporting platform after the pressure is relieved. (at this point, the number of rotations in the Manual should be actually calculated).

5. When removing the bolt, can it be more than the number of rotations recommended in the manual?

As long as the stroke of the hydraulic lift is sufficient, there is no problem with two rotations. In this case, as long as the distance sleeve is high enough, the nut can be removed all at once. Some manuals recommend 1/2-3/4 turns, sometimes it won’t be loose after two times. At this time, as long as we detect the stroke of the lifter (the lifter does not carry a load, the stroke can be calculated until the oil is pressurized, and then how much can be rotated according to the stroke). In fact, it is sufficient to detect whether the lifter stroke is sufficient, mainly when the bolt is pulled to the specified pressure at one time when the nut is tightened, and whether the lifter piston seal is exposed and oily is sufficient. At the same time, the lift of the puller at the moment is the elongation of the bolt. Then how many revolutions we can make can probably be estimated.

6. Why doesn’t the tensioner rotate during installation?

During installation, after the tensioner pulls the bolt into place, the nut is tightened. At this time, the oil pressure is released, and the force is transferred to the nut. On the other hand, when disassembling, the force is transferred to the lifter, which is why the lifter rotates when disassembling.

7. Can a single bolt be pulled up during disassembly and installation?

No, it must be installed and removed in pairs.

8. Can elastic bolts be replaced individually?

No, it must be replaced in pairs.

Now, tell us the problems you have encountered during the use of the bolt tensioner, and our engineers will answer your various questions online. TorcStark is at your service anytime!