Basic Introduction Of Manual Hydraulic Pump

Basic Introduction Of Manual Hydraulic Pump

As a simple and convenient hydraulic power source, the ultra-high pressure manual hydraulic pump is widely used in many fields such as the shipbuilding industry, coal mining machinery, petrochemical, metallurgy, electric power and heavy machinery. It also has the advantages of small volume, light weight, easy to carry and high safety.

TorcStark HP series ultra-high pressure manual hydraulic pumps have a working pressure of 100~300MPa and are equipped with a pressure relief valve. In order to prevent pressure overload, the pump is also equipped with a safety relief valve. It adopts a two-stage flow design, the displacement is 33CC at the first low pressure, and the displacement is 1.6CC at the second high pressure, which realizes the low-pressure large-flow oil supply under the constant power condition, the high-pressure small-flow oil supply, which saves time and improves Efficiency.

The overall size of the pump is 585*124*160mm, and the total weight with oil is about 8.8Kg. This pump is convenient and flexible to use, has low labor intensity, and is durable. It is an ideal ultra-high pressure hydraulic power source.

The function of a manual hydraulic pump is to convert the mechanical energy of a power machine (such as an electric motor and an internal combustion engine) into pressure energy of a liquid.

The basic principle of its work is that the motor drives the cam to rotate. When the cam pushes the plunger upward, the volume of the seal formed by the plunger and the cylinder is reduced, and the oil is squeezed out of the seal volume and discharged to the place where it is needed through the one-way valve. go. When the cam rotates to the lower part of the curve, the spring forces the plunger down to form a certain degree of vacuum, and the oil in the oil tank enters the sealed volume under the action of atmospheric pressure.

The cam causes the plunger to rise and fall continuously, the sealing volume periodically decreases and increases, and the pump continuously sucks and discharges oil.

The manual hydraulic pumps currently on the market are generally plunger pumps, with single-pole and double-stage forms. All its valves are usually concentrated on the plunger pump, and the structure is relatively compact. The reversing valve and the plunger pump are divided into two independent parts, but they can be used in combination.

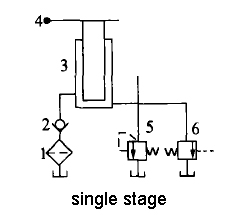

The structure of the single-stage plunger pump is relatively simple, and its principle is as follows:

When the 4 handle is lifted up, the hydraulic oil enters the lower cavity of the 3 plunger through the 1 filter and the 2 one-way valve, and the hydraulic pump sucks oil; when the 4 handle moves down, the 3 plunger supplies oil to the system. Valve 5 is a safety valve, and valve 6 is an unloading valve. Single-stage pumps provide intermittent pressurized oil, and the displacement is not adjustable, and can only be low-pressure large flow or high-pressure small flow. It is generally a low and medium pressure pump.

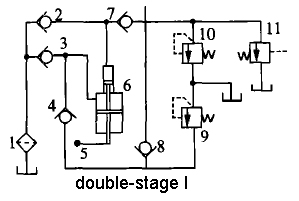

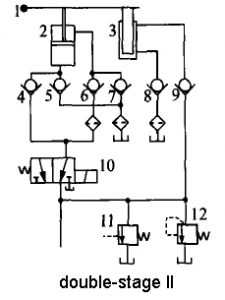

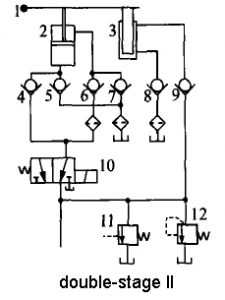

The two-stage plunger pump has two different structural forms, and the principle is as follows:

Schematic diagram of two-stage I-type hand pump. Lift the handle 5, and the hydraulic oil enters the large and small cavities of the plunger through the filter 1, the one-way valve 2, and 3 respectively. When the handle 5 is pressed down, there are two situations: when the system is at low pressure, the one-way valves 4, 7, and 8 are opened, and the two pumps supply oil to the system at the same time, and the flow is the largest. When the system is at high pressure, the sequence valve 9 is opened (the setting pressure of the sequence valve is generally 1 MPa), the one-way valve 8 is closed, the low pressure oil of the large pump is directly returned to the oil tank, and the small pump supplies oil to the system alone, and the flow is small. Valve 10 is a constant pressure valve, and valve 11 is an unloading valve. The two-stage I-type hand pump has large low-pressure flow, small high-pressure flow and intermittent oil supply.

Schematic diagram of two-stage type II hand pump. Valve 11 is a constant pressure valve, and valve 12 is an unloading valve. In the low-pressure area, when the handle 1 moves upward, the lower oil chambers of pumps 2 and 3 are supplied with oil, and the upper chamber of pump 2 is supplied with oil. When the handle 1 moves downwards, the upper cavity of the pump 2 enters oil, and the lower cavity of the pumps 2 and 3 supply oil to the system. In the low pressure area, the pump can continuously supply oil to the system. When entering the high pressure zone, the system pressure increases, and the hydraulic control valve 10 works in the right position, so that the oil circuit composed of pump 2 and check valves 4, 5, 6, and 7 is unloaded, and pump 3 and check valves 8, 9 The composed oil circuit supplies oil to the system. Compared with the two-stage type I, the two-stage type II hand pump can realize continuous oil supply, which improves efficiency and saves time, but it is also a pump that supplies oil with a large low-pressure flow and a small high-pressure flow.

In daily use, manual hydraulic pumps may have some problems, which may be due to improper operation or aging of the machine. When encountering problems, TorcSatrk recommends looking for problems from the following three aspects:

- Check the internal leakage of the boom cylinder:

The easiest way is to raise the boom to see if there is a clear free fall. If the drop is obvious, disassemble the oil cylinder for inspection, and replace the sealing ring if it is found to be worn.

- Check the control valve:

First, clean the safety valve and check whether the valve core is worn out. If it is worn out, replace it. If there is no change after the safety valve is installed, check the abrasion of the control valve spool. The use limit of the clearance is generally 0.06mm, and it should be replaced if it is severely worn.

- Measure the pressure of the hydraulic pump:

If the pressure is low, make adjustments. If the pressure still cannot be adjusted, it means that the hydraulic pump is severely worn.

For example, the main reasons why the boom cannot be lifted with load:

- The hydraulic pump is severely worn. In low-speed operation, the internal leakage of the pump is serious; in high-speed operation, the pump pressure increases slightly, but due to the wear and internal leakage of the pump, the volumetric efficiency drops significantly, making it difficult to reach the rated pressure. Long-term operation of hydraulic pumps aggravates wear and oil temperature, which causes wear of hydraulic components and aging and damage of seals, loss of sealing ability, deterioration of hydraulic oil, and finally failure.

- The selection of hydraulic components is unreasonable. The specifications of the boom cylinders are 70/40 non-standard series, and the seals are also non-standard, so the manufacturing cost is high and the seals are inconvenient to replace. The small cylinder diameter of the boom cylinder will inevitably make the system set pressure high.

- The design of the hydraulic system is unreasonable. The control valve and the full hydraulic steering gear are connected in series with a single pump. The set pressure of the safety valve is 16MPa, and the rated working pressure of the hydraulic pump is also 16MPa. Hydraulic pumps often work under full load or long-term overload (high pressure) conditions, and the system has hydraulic shocks, long-term non-changing oil, contaminated hydraulic oil, aggravated the wear of the hydraulic pump, and caused the hydraulic pump casing to burst (such failures have bever been found.)

Finally, no matter you encounter any problems, please troubleshoot and deal with them according to the actual situation. If you cannot repair it, it will be a perfect choice to ask professional maintenance personnel for help.

The application range of ultra-high pressure manual hydraulic pump is very wide. It can provide power for cutters, hydraulic clamps, punching machines and other construction tools in the field operations of electric power, railways, rescue, construction and other industries. It can also be used for static and blasting testing of pipe fittings, hoses, valves, pressure vessels, cylinders, etc., static and dynamic testing of aerospace accessories after maintenance, safety valve calibration, water bubbling test of valves and wellhead devices, gas pressure regulator testing, automobile brake system testing, and communication cable inflation equipment, etc.

The high-pressure hand pump is a very easy-to-use hydraulic equipment. It is simple to operate, easy to carry and move, widely used, and inexpensive. TorcStark single-acting aluminum hand pump is of good quality, light weight, easy to carry, and cheap. And we also sell other types of hydraulic pumps, such as electric hydraulic pumps, gasoline-driven hydraulic pumps, pneumatic hydraulic pumps, single-stage, two-stage, three-stage and so on.

Contact us now for the latest price list of hydraulic pumps.