What Special Properties Does the Cemented Carbide Non-Standard Knife Have? – UKO Blog

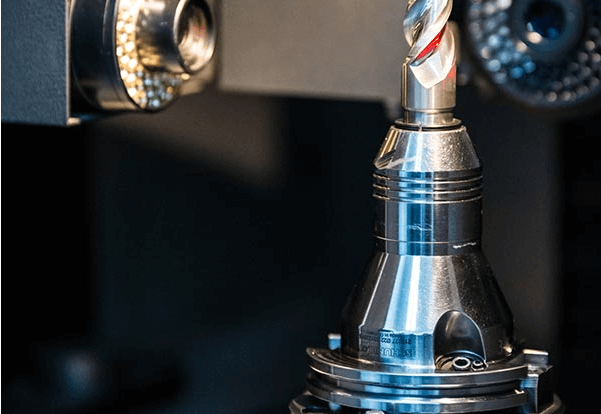

Cemented carbide non-standard tools are used as industrial teeth, using one or more refractory metal carbides (WC, TiC, etc.) as the hard phase, transition metal (Co, etc.) as the bonding phase, and powder metallurgy Technology to produce multi-phase materials.

As a non-standard tool for cutting cemented carbide, the commonly used carbides are WC, TiC, TaC, NbC, etc., and the commonly used bonding phases are Co, Ni, Fe, etc. The strength of cemented carbide non-standard tools mainly depends on the content of the bonding phase.

Cemented carbide non-standard tools have the advantages of high strength, high hardness, wear resistance, corrosion resistance, high temperature resistance, and small linear expansion coefficient, and are widely used in many industrial production and processing operations.

Cemented carbide non-standard tools have the following special properties:

Tensile strength: The tensile strength of cemented carbide non-standard tools is 750-1500MPa, which is about 1/4 of the compressive strength. Because there are many factors that affect the plasticity of cemented carbide non-standard tool materials, the tensile strength of a cemented carbide non-standard tool is usually within a certain range.

Impact toughness: The impact toughness of cemented carbide non-standard tools is lower than that of high-speed steel. The impact toughness of YG8 alloy with better performance is 30-40KJ/m2, while the impact toughness of W18Cr4V high-speed steel is 180-320KJ/m2.

The impact toughness of TiC-containing carbide non-standard tools has decreased. When the TiC content is increased from 6% to 10%, the impact toughness is significantly reduced. Temperature has a certain effect on the impact toughness of WC-Co cemented carbide non-standard tools. At higher temperatures, the impact toughness is improved.

Since the impact toughness of cemented carbide non-standard tools is lower than that of high-speed steel, it is not suitable for use in situations where there are strong impacts and vibrations, otherwise it may cause a sharp edge. The impact toughness of non-standard cemented carbide tools fluctuates greatly, and its absolute value is related to the test method. Therefore, when comparing the impact toughness of non-standard cemented carbide tools, the same instrument should be used to compare samples of the same size and shape.

Fatigue strength: As cemented carbide tools usually work under dynamic conditions, their fatigue strength is very important. The higher the content of cobalt in the non-standard carbide tools, the higher the fatigue strength. The fatigue strength of cemented carbide non-standard tools has a great relationship with the surface quality of the sample. The better the surface finish, the higher the fatigue strength.

Cemented carbide non-standard tools are very important in the production and processing of non-standard cemented carbide products. As key parts and tools, they are used in various industries and have indelible effects on production. Understand its special performance to make better use of it.