How To Choose The Best Glue For Wood Projects – 8 Options

So I was in my shop about to do a glue-up on my desk project, and I thought to myself, what is the best glue for wood? So I did some digging, and I wanted to share what I learned here.

Of the several different types of wood glues available, I find that regular PVA yellow glue meets most of my needs, although I’m starting to use Hide Glue more and more (I’ll explain below).

A common trait among the wood glues is that they create a bond stronger than the wood itself. That means you’re more likely to break the wood before you actually break apart the glued joint. (Woodgears.ca did a strength test proving these claims here).

Keep reading to learn the differences between the different wood glues and when you should be using each.

PVA Glue (Yellow Glue) – Best Glue For Wood

So like I already mentioned, this is a standard wood glue. Common PVA glues you’ll see are Titebond and Elmers wood glue. You can find this at any hardware or your big Home stores. Hobby stores will also likely have PVA glues.

The working time (or the time you have to get clamps on after starting a glue up) on yellow glue is around 10 minutes, so you don’t have a lot of time and this can be stressful. It’s best practice, if using Yellow glue, to not do too many glue joints at the same time. Break it down into multiple glue-ups, if possible.

Once clamped, it takes about 60 minutes to set. So you’ll want to leave it clamped for the duration of this set time.

Yellow glue will leave a clear glue line at the wood joint, making it ideal for a concealed and good-looking finished product. But that doesn’t make it ok to leave glue squeezeout on the material.

You always want to remove any squeezeout from the glue joint by using a paint scraper or a nice sharp wood chisel.

For a great finished glue joint, Yellow glue works best when:

- It’s for an indoor project, as standard PVA glue is not waterproof.

- You’re gluing long grain to long grain. The water-based glue will soak into end grain like a sponge, which is not good for joint strength.

- The joint is tight without gaps. PVA glue is not designed to fill voids in the wood joint.

Read more about PVA wood glue here.

Waterproof Wood Glue

Here’s another common type of wood glue that probably gets used more often than it should. It’s a bit higher priced than yellow glue, and it can also be found just about anywhere that sells wood glue. Titebond III is a popular brand you’ll see in a lot of how-to videos. I personally have and use this on most projects myself, although after researching for this article I will be switching over to regular Titebond Yellow glue.

The working time, or the time you get before the glue sets once contact is made, is much better with this type of glue. Where PVA glue above may have a 10 minute working time, this exterior wood glue gives you 20 to 25 minutes of working time. This can be a huge advantage, especially when doing complicated glue-ups. This is the reason I have always liked using exterior wood glue; it keeps me from having to be so rushed when getting a glue up ready for clamps.

Exterior wood glue will also be less solid, once completely cured, compared to Yellow glue. This is because it’s made for outdoor furniture and projects, which tend to expand and contract more with the changing outdoor humidity levels. So they make this type of glue with a bit of flexibility in the finished joint.

The line left at the glue joint itself will not be as invisible than a Yellow glue joint. Exterior glue dries and leaves more of a tan colored line at the joint. This can be unfavorable for many projects, especially if you’re working with light colored woods like Pine and Maple.

But overall, this option is the best glue for wood projects that will be exposed to the outdoors, or projects requiring more complicated glue-ups when you need a longer working time. A few examples of when you should use exterior wood glue can be found on my post 11 Easy Beginner Woodworking Projects.

Exterior waterproof wood glue is best when:

- You’re doing exterior projects that will be exposed to swings in temperature and humidity.

- Like Yellow glue, you also want tight joints, as this glue is not made to fill voids and gaps.

- Also, like Yellow glue, you want long-grain to long-grain joints for this glue. End grain is best joined by using Polyurethane glue (see below).

Polyurethane Wood Glue

Poly glue, like the standard Gorilla glue or a variation of Titebond, is also waterproof and can be used for exterior projects. It’s also a bit higher priced than Yellow glue.

Depending on the composition of the glue, so this varies from manufacturer to manufacturer, Poly glue may have a working time of somewhere around 20 minutes. So like the exterior wood glue explained above, this can be a game changer when it comes to doing large glue ups with multiple joints being glued at the same time.

Polyurethane glue is activated by the moisture in the air. This means that once you open the bottle, it may only have a shelf life of a couple of weeks. The entire bottle full can harden on the shelf, with the lid closed. So only buy this stuff in as small of quantities as you can get away with. Basically, if you buy a big enough bottle to last you for several weeks, you bought too much. It may be better to get multiple small bottles, than one large one.

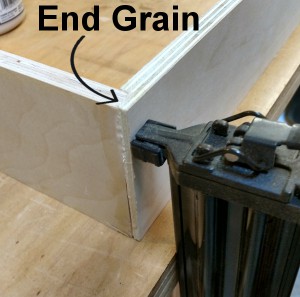

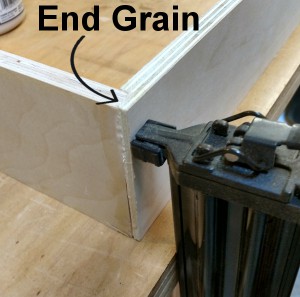

Poly glue doesn’t soak into the wood grain the same way other glues do. This makes it the best glue for wood joints that have a portion of end grain being glued. So for instance, in my recent how-to guide for building a drawer, the corners were glued together and brad nailed. I didn’t have any Poly glue so I used what I had, exterior wood glue. Had I not been using any nails for this, a Polyurethane glue would have been the better choice, as the edges of plywood have both edge grain and end grain.

So overall, Polyurethane wood glue is best when:

- The project is for outdoor use, as this glue is waterproof and flexible.

- A portion of the glue joint will be end grain, as opposed to long grain.

Hide Glue

There is an old, traditional style of hide glue that comes in a solid form. You have to disolve it and keep it at 140 degrees F to use it.

As it cools, it becomes very adhesive, and as it fully dries it becomes an incredibly strong bond.

This is not convenient or quick, so it’s not popular in today’s woodworking.

But you can buy liquid hide glue that works at room temperature and even has an impressive working time.

Hide glue’s other benefits include the ability to be easily sanded and scraped (it dries very hard), it’s reversible when you add moist heat to the joint, and it doesn’t swell the wood fibers so tight fitting joints go together much smoother.

Hide Glue is best when:

- You require long working time, like with complicated glue ups

- You’re not building kitchenware (it’s not food-grade)

- You are worried you may need to undo the glue joint and start over

- The joint is very tight-fitting

This glue works great for complicated glue ups, like dovetail boxes. But overall it’s an impressive and strong glue that can be used for almost any wood project.

Read more about hide glue here.

Epoxy Glue

This type of glue comes in 2 parts. One is the resin, the other is the hardener. It doesn’t work unless you mix them together. You buy them packaged in 2 different containers, which you’ll have to mix together before applying. Some types are easier to use than others, like the one pictured here, you can squeeze out both parts at the same time for easy portion control and mixing.

This type of glue is more expensive and less practical to use for regular wood joinery.

However, there is a place in a woodshop for this type of wood glue. If you have a wood joint that does not dry fit very tightly, Epoxy can fill that gap. So for example, if you cut a mortise and tenon joint, and when dry-fit together the tenon has some wiggle room, epoxy wood glue is a good choice.

Overall, it’s a good idea to have Epoxy wood glue in your shop, for these cases:

- The wood joint has some slop to it and doesn’t fit together tightly when dry, epoxy can fill the void.

- If gluing up a panel and the edge of the board is damaged or not perfectly plat, epoxy may be able to fill the gap.

- If you have a void, like a knot that came out, fix it with Expoxy using this method here.

Other ‘Special Case’ Glue Options

CA Glue

This is your super glues, and it’s an instant cure glue. In woodworking, you may find some use for CA glue if you have a piece of wood with a corner broke off.

For example, I was hand planing a board slight cross-grain, and when I ran off the corner, a piece chipped off.

This would have been really noticeable in the final product, so I used super glue and pushed it back together. I sanded it down a bit and continued working.

You can also use CA glue for creating custom inlay projects. Click Here to learn how.

Hot Glue Gun

Hot glue guns melt a stick of glue and push the melted glue out of the end of the gun. This is basically a really sticky substance, and does not chemically bond to the material. But because it will pretty much stick to anything, it’s good for some crafts, certain repairs, and temporary gluing needs.

I personally don’t have a need for hot glue in my wood shop, but we have used it for household DIY repair jobs inside.

Spray Adhesive

Spray adhesives come in many different brands, at different strengths, and with different dry times. Generally, best practice is to spray both surfaces being glued together, let them dry just until they get tacky to the touch, then put the pieces together.

I’ve used spray adhesives for attaching scroll art templates onto a piece of plywood for my scroll cutouts. Also, it’s great for making woodworking jigs if you need to attach sandpaper to wood.

For example, for my miter sled project I attach sandpaper to the miter fences, and it makes it much easier to hold the board securely in place (no slipping).

Wood Glue FAQ

What is the best wood glue for cabinets?

Cabinetry uses a lot of plywood. Typically the entire carcass of the cabinet is basically a plywood box, joined by inserting the edge of a piece into a matching dado or rabbet of another piece. This type of joinery means a lot of your joint stress will be at the edge of any given piece of plywood since you’re gluing mostly Edge-to-Face.

So for this, I would recommend Polyurethane glue, as it does not soak into the end grain like PVA glue does since it’s not water-based. Polyurethane glue is ideal in joints that involve end grain like you’ll find along every edge of a piece of plywood.

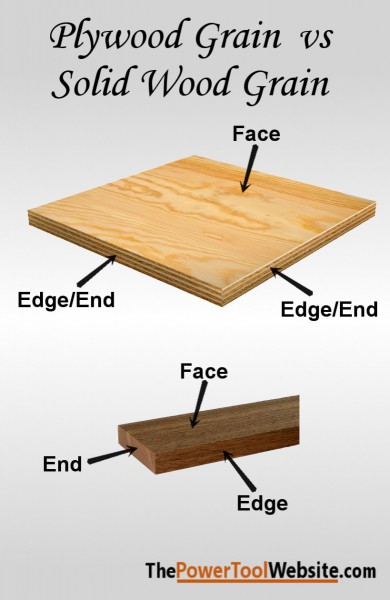

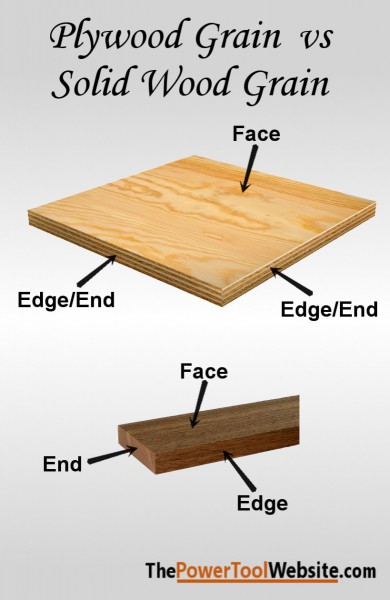

Plywood is different than solid wood, in that each layer has alternating grain direction. That means you don’t have one side being the ‘Edge Grain’, and the adjacent side being ‘End Grain’ like you do on solid wood.

Instead, you have 50/50 edge and end grain along each side of the plywood, making it notorious for soaking up water-based glues. And if your glue soaks into the wood too much, you end up with a glue-starved joint, which means it’s weaker.

Can you use Gorilla Glue on wood?

While I believe this question is referring to the original Gorilla glue, I must add that there are multiple options now from the Gorilla Glue brand.

However, if you are wondering about the original Gorilla Glue, then the answer is YES.

Gorilla glue was originally formulated as a water-activated polyurethane glue, which I cover in more detail above. The glue bonds very well to wood, similar to PVA glues. However, it’s not specifically made just for wood, and there is some downside, also covered in detail above.

But if you’re asking this question, you likely have some Gorilla Glue on hand, and I’m here to tell you that yes, you can use it for wood joints.

If you’re just a fan of the brand Gorilla Glue, then you should know that they now have an entire line of glue products, including PVA wood glue, Epoxies, and even Super Glues (CAs).

How do you glue wood together?

- Dry fit the joint to make sure it fits tightly together. Not so tight that it’s hard to take apart when dry, but snug so there’s very little wiggle, preferably none at all. Or if you’re gluing 2 edges, say in making a panel for a table top, just be sure the edges are good and flat, and in laying the boards together you see no gaps.

- Apply wood glue evenly to the entire surface making contact, on BOTH PIECES. Rub the glue in and spread it evenly so it coats the entire surface. If the joint is being strengthened with say pocket screws, then you can get away with rubbing it pretty thin near the edges, to reduce squeeze out.

- Put the pieces together and apply pressure using any number of clamping techniques. Depending on the type of joint, or the size of the material, you may be able to use quick clamps, or you may need bar clamps or pipe clamps. If the size of the material is such that you can’t get a clamp on it, and you need to apply downward force on the joint, you can set weights on the top piece until the glue cures.

- Clamping time varies for different types of glue, but I recommend you clamp for a minimum of 60 minutes. Then if you don’t need to remove the clamps in 60 minutes, leave it clamped until the next day. Also, you don’t want to apply any stress to that joint for the first 24 hours.

For more on gluing up a nice flat panel, check this post out.

TIP – If you have glue squeeze-out (which you should have if you used enough glue) on a surface that will be exposed, you can remove clamps after 60 minutes and clean off the squeeze-out with a sharp chisel or a glue scraper.

And anywhere there’s glue in the wood grain exposed, your final finish might make it stand out and very noticeable. So scrape it off with a chisel, then sand that joint really good before finishing.

Here’s a quick video on the process from the guys over at Woodworkers Journal:

What is the best wood glue for outdoor projects and furniture?

Outdoor projects demand a different type of wood glue than indoor projects, which you are obviously aware of by asking this question. What you may not realize is which glue works best outside, and why.

So I would suggest using 1 of 2 different types of glue for outdoor projects. Titebond III, and the original Gorilla Glue.

Titebond III is waterproof, so it does not lose integrity when moisture is introduced to the glue joint. It has a longer working time than regular indoor wood glue, and it also retains some of its flexibility after it cures. This is important because furniture that sits outside has a constant fluctuation in moisture content, due to changing humidity levels.

And then you have the original Gorilla Glue. This is a polyurethane glue, so it is also waterproof. It’s best used on joints that have some end grain, or on plywood joinery because Poly glues don’t soak into the end grain of the wood like water-based glues, which would be the Titebond variations.

So for outdoor projects when the joint is long-grain to long-grain, use Titebond III. For outdoor projects with plywoods, or wood joints that include end grain on one of the mating surfaces, you’ll be better off using Gorilla Glue.

What is the best wood glue for indoor furniture?

The article above covers all the different wood glues and is mostly geared towards indoor wood projects and furniture. But in summary, regular Yellow glue, like the original Titebond, is the best glue for wood projects for indoors like furniture.

Exceptions would be if you have complicated glue-ups that require additional time to set up your clamps, Titebond III will provide you with a longer working time than Titebond.

If you have end-grain in the joint or are building something with plywood and are gluing the edge of that plywood to another piece of wood, Gorilla Glue works better. Gorilla glue doesn’t soak into the end grain like Titebond water-based glues. And when most of your glue is soaked up into the end grain, you have a weaker joint.

But for me, the original Titebond PVA glue is all I need for probably 90% of the furniture I make.

Which glue works best for crafts?

Crafts are typically things that don’t have the amount of stress put on the joints as a piece of wooden furniture would have. Crafts also may not be that easy for clamps to be applied properly for a gluing process. Also, crafts tend to be quicker projects than furniture building.

So if you’re into building crafts, I would recommend having:

- A Good hot-glue gun

- A few variations of spray adhesives

- CA glue, also known as super glue.

Each of these would likely serve you well in different scenarios. You can read above for more details on each one of these 3 types of glue.

What glue is considered high strength?

In regards to gluing wood, any glue designed for wood joints is going to likely be stronger than the wood itself.

With that said, there are different levels of strength, which vary from different types of glue, and different types of wood.

But basically, they found that Gorilla glue and Titebond III offer some of the highest levels of strength in a glue joint. But regular Yellow glue (like Titebond 1), also performs really well. Even hot glue holds its own in these stress tests, which surprised me.

But if you’re looking for the highest strength wood glue, I would recommend going with Titebond III or Gorilla Glue.

Related:

All About PVA Wood Glues

All About Hide Glue

How To Glue Up Flat Panels For Your Table Projects

Access My Free Resources Page For Woodworking Plans

Sign up below for some great beginner woodworking tips and projects sent to your inbox!